|

||

Being structured with non independent bubble cell can represent excellent air permeability. Also represents the good thermal insulation performance equivalent to the commercially available material. |

| FB1010 | FB1510 | Phoenol Foam material | PP Foamed material | |

| weight(g/m2) | 1000 | 1500 | 270 | 720 |

| Thickness(mm) | 10 | 10 | 10 | 9 |

| Density(g/cm3) | 0.10 | 0.15 | 0.03 | 0.08 |

| Air permeability (g/cm3/cm2/s) |

26.2 | 14.8 | 0 | 0 |

| Equivalent Open Area(cm2/cm2) | 0.005 | 0.025 | 0 | 0 |

| Thermal conductivity (W/mŽ¥K) |

0.034 | 0.038 | 0.020 | 0.051 |

| *As for the data for Phoenol Foam or PP Foam the data was taken by original manufacturers catalog. |

| Air Permeability | JIS L 1096 General textile testing method Air permeability tester- Fragile measurement |

| Equivalent Open Area Measurement | By Kuraray method |

| Thermal Conductivity | JIS¡¡A1412-2 Thermal current tester by Organization of Construction Material Testing Center |

|

|

|

|

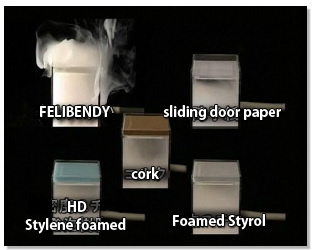

Acrylic cup with FELIBENDY board beneath

and smoked gas injected to show the air permeability. A rigid board structured FELIBENDY can present better air permeability than the paper used for sliding door in Japanese interior which is said to have fairly good air permeability. |

| FELIBENDY Board type can be used for interior or wall to give better air permeability as well as thermal insulation material. |